Metal Polishing and Buffing Services

We offer best-of-class polishing and buffing services for a variety of materials in sheet and plate forms. Most importantly, metal service centers make use of our mechanical polishing services and therefore produce better results.

Flat Sheet Polishing & Buffing

We Buff & Polish Anything

A variety of materials such as aluminum, brass, bronze, stainless steel, titanium and other alloys can be polished and buffed to perfection.

Hand or Machine

Our polishing and buffing services encompass hand buffing, mid polishing, and final polishing, using a variety of techniques.

The Largest Buffing Machine.

We possess one of the largest buffing machines used in the industry. It can accommodate 160 inches wide and 460 inches long sheet/plate material.

Quality. Quality. Quality.

Our facility also comprises measuring equipment such as ultrasonic gauges, micrometers, and profilometers, which can measure and check dimensions in polished materials.

Speed

We specialize in tight turn-around times and end-of-chain processing.

Available Metal Polish Finishes

#8 Mirror Finish

A #8 Mirror Finish is a high reflection, high luster finish with minimal haze. The metal to be polished play a significant role in the final appearance, such as color and grain

Mechanically

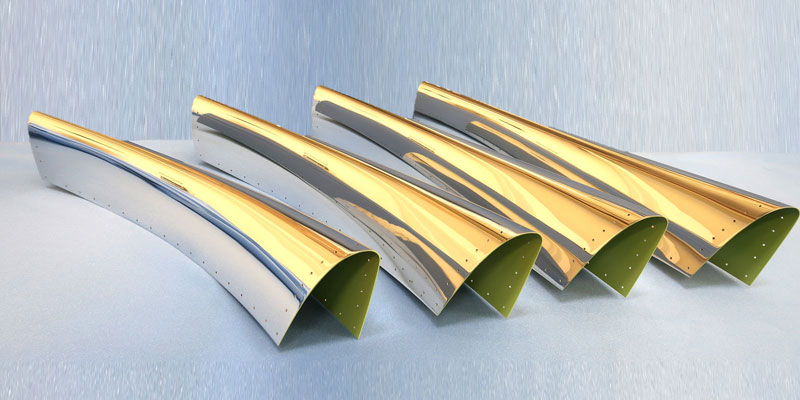

Polished Skin Quality (Boeing D6-83818)

Mechanically Polished Skin Quality

(Boeing D6-83818)

An ideal mechanically polished sheet or plate will have uniform color, brightness, and a high reflectivity over the entire surface. The material will be completely free of all scratches, abrasions, pits, and out-of-flat conditions. The reverse or stencil side of the material will be equal to or superior in quality, both structurally and in terms of appearance, to mill standards.

IntermediateSkin Quality (Boeing D6-83818)

Intermediate Skin QualityIntermediate Skin Quality material exhibits a very good quality clad surface finish but not the high quality appearance of a mechanically polished skin. It is intended for use in airplane liveries that are painted. The final delivered surface texture shall be compatible with the surface roughness requirements for good paint adhesion. Intermediate Skin Quality shall is procured in accordance with D37200.

Class 1: Mechanically Polished Skin Quality Material (Boeing D6-9002

Class 1: Mechanically Polished Skin Quality Material

(Boeing D6-9002)

Mechanically Polished Skin Quality material exhibits a very high quality reflective appearance intended for airplane liveries which are unpainted. The appearance of the Mechanically Polished Skin Quality material is a uniform high level of color, brightness and reflectivity. Mechanically Polished Skin Quality material is procured in accordance with D37200.

Class 2: Intermediate Skin Quality Material (Boeing D6-9002

Class 2: Intermediate Skin Quality Material

(Boeing D6-9002)

Intermediate Skin Quality material exhibits a very good quality clad surface finish but not the high quality appearance of a mechanically polished skin. It is intended for use in airplane liveries that are painted. The final delivered surface texture shall be compatible with the surface roughness requirements for good paint adhesion. Intermediate Skin Quality shall is procured in accordance with D37200.

Type I Finish: Polishing of Aluminum Alloy Parts (Bombardier BAPS 136-120)

Type I Finish:

Polishing of Aluminum Alloy Parts

(Bombardier BAPS 136-120)

This specification establishes the requirement for qualification and process control for the

polishing of aluminum alloy parts to a matte to semi-matte finish.

Type II Finish: Polishing of Aluminum Alloy Parts (Bombardier BAPS 136-120)

Class 1:Cosmetic Polishing (Gulfstream GAMPS 4001)

Class 1: Cosmetic Polishing

(Gulfstream GAMPS 4001)

Cosmetic Polishing of G-IV alclad aluminum only. Metallic surfaces will have a uniform, high-luster gloss, with no evidence of abrasions, scratches, or other visible blemishes.

Class 2:Cosmetic Polishing (Gulfstream GAMPS 4001)

Class 2: Cosmetic Polishing

(Gulfstream GAMPS 4001)

Cosmetic Polishing of Bare (Unclad) Aluminum. Metallic surfaces will have a uniform, high-luster gloss, with no evidence of abrasions, scratches, or other visible blemishes.

Class 3:Cosmetic Polishing (Gulfstream GAMPS 4001)

Class 3: Cosmetic Polishing

(Gulfstream GAMPS 4001)

Cosmetic Polishing of Alclad Aluminum. Metallic surfaces will have a uniform, high-luster gloss, with no evidence of abrasions, scratches, or other visible blemishes.

Class 4:Cosmetic Polishing (Gulfstream GAMPS 4001)

Class 4: Cosmetic Polishing

(Gulfstream GAMPS 4001)

Cosmetic Polishing of Stainless Steels (CRES), Low Alloy Steels, Nickel-Base Alloys, Copper-Base Alloys (i.e. Brass, Bronze), and Chromium and Nickel Plating. Metallic surfaces will have a uniform, high-luster gloss, with no evidence of abrasions, scratches, or other visible blemishes.

Class 5:Cosmetic Polishing (Gulfstream GAMPS 4001)

Class 5: Cosmetic Polishing

(Gulfstream GAMPS 4001)

Cosmetic Polishing of Titanium Alloys. Metallic surfaces will have a uniform, high-luster gloss, with no evidence of abrasions, scratches, or other visible blemishes.

Several other finishes available

REQUEST A QUOTE TODAYADDITIONAL SERVICES

Whether you need surface laminating, crating, packing or Just In Time inventory programs-

we have the experience to handle your project turn-key.

PROTECTIVE LAMINATION

GMS seals your project with wide selection of laminating films to best fit your next stage in processing. Film materials include PVC, PE, Teflon, and others. The protective film will keep your project scratch free for transport, during machining (drilling, forming, laser/waterjet cutting) or storage.

CRATING & PACKING

We pack and crate your finished material for travel around the corner or around the world. GMS can handle your unique requirements to ensure your material is safeguarded during transit.

STORAGE & JIT DELIVERY

We can inventory and drop-ship large or small quantities. GMS inventory gives you the flexibility and timing you need.